Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

Model No.: TU-013

Tolerance: 0.02mm

Material: Aluminum 7075

Sample Lead Time: 7 Days

Finish: Sandblasting / Clear Anodize

Product Size(mm): ф42*141.5

Productivity: 3000/Month

Transportation: Ocean,Land,Air

[]

Precision CNC Turning parts for DMS, material: aluminum 7075, surface treatment: sandblasting/transparent anodizing. CNC turning parts for deep muscle stimulators.

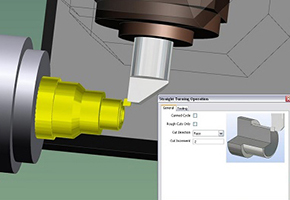

Our CNC turning centers are equipped with multi-station turrets or powered turrets. This machine tool has a wide range of processing capabilities, and can process linear cylinders, diagonal cylinders, arcs and various threads, grooves, worms and other complex parts, as well as six lathes. The processing size of the largest diameter can reach 860mm, and the thinnest 0.23mm of a single product. The materials for cnc turning and CNC Milling are: copper/bronze/H62, titanium/TC4 aluminum 6061, 6063, 6061-T6, 7075, 5052.2017.6082. Stainless steel: 1.4305, 1.4301, 316, steel: Q235, 45#, A3, 718H, S136, SKD11.. Plastic: POM, Teflon, PA, (PA66) PC, PMMA Product surface treatment: anode (transparent, black , Blue, yellow, various colors can also be customized). Sandblasting, spraying, passivation, laser engraving LOGO, silk screen LOGO.

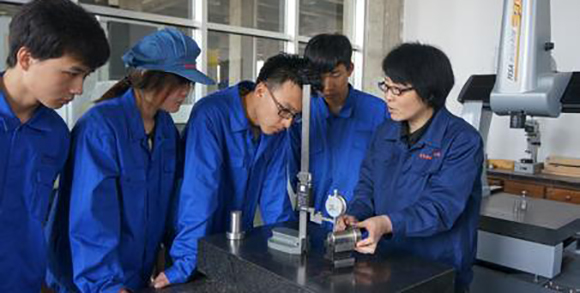

从From the purchase of raw materials to the shipment of CNC turning parts, we have established a complete quality control system. The entire process of the operator is operated by SOP, and each processing step of the IPQC product is tested to ensure that the product meets the requirements for the next CNC Machining and turning. 100% full-scale inspection of the first machined part. FQC tests the products and ships them before shipment. Engineering and technical personnel regularly carry out processing and maintenance settings, and update processing tools in time. Our inspection tools are: digital calipers, micrometers, height gauges, profile projectors...tolerances can measure +/- 0.01mm and 0.001mm.

A strong precision CNC Machining and turning technology team is the basis for ensuring product quality. Our engineers are committed to continuous improvement of CNC turning technology. Comprehensively understand and master the basic processes and key technologies of CNC turning and CNC milling programming. CNC machining and turning tests should be carried out for important processing procedures of CAD/UG/Master CAM software.

The ISO9001:2008 quality system covers all departments. We obtain the best product quality from the following aspects: the accuracy of the equipment to meet the product quality of CNC machining and turning processing technology, the choice of tools and the reasonable choice. Auxiliary fixture. Train workers. All aspects of CNC lathe parts processing inspection

Every CNC machined and turned part undergoes rigorous testing, including initial inspection, process inspection, and final inspection. The inspection work is closely linked to the CNC turning process control. The quality of each process or possible quality problems are rejected. Unqualified products make it impossible to order or leave the factory, so as to achieve the purpose of process control

We focus on short-term delivery and promise to provide samples every week. For simple CNC turning parts, please complete the sample within 3 days. The factory provides 2 to 3 sets of CNC turning centers for sample production. The workers are divided into two groups to ensure that the machine produces 24 hours a day. In order to meet these services, we also have a qualified supplier base so that we can provide a complete cnc turning service quality from the surface to the part of the product LOGO logo.

Our various precision CNC turning centers enable us to provide customers with the best prices for the production of custom machined parts. Regardless of the size or specifications you order, we have equipment that can do the job correctly and produce parts when and how to demand them.

CNC machining can import your Para-Solid 3D image files, .PDF and IGES, STEP or SOLIDWORKS files. Please send your 3d works and PDF quotation.

Product Categories : CNC Machining Turning

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.