Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

Model No.: TU-015

Tolerance: 0.02mm

Sample Lead Time: 3 Days

Material: Aluminum 6061

Finish: Sandblasting / Clear / Black Anodize

Product Size(mm): ф160*35

Productivity: 13000/Month

Transportation: Ocean,Land,Air

[]

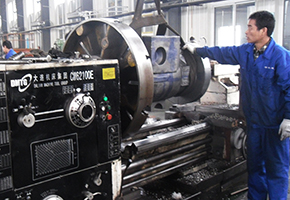

Provide CNC Turning for various aluminum alloys,Maximum turning diameter ф860mm.Processing accuracy 0.01mm.CNC Turning Aluminum parts provide secondary services: Sandblasting,Anodizing,Nickel Plated,laser engraving LOGO.

Our CNC turning has three configurations: Single Turret Single Spindle, Twin Turret Twin Spindle.As well as automatic feeding function.Using Esprit software CAM programming,The following cutting action can be performed:The following cutting action can be performed. There are six lathe. Machining tuinring size of the largest diameter can reach ф860mm.The cnc turnining and CNC Milling Machining materials are:Aluminum 6061,6063,6061-T6,7075,5052.2017.6082.

Alloy Steels,Carbon Steel,

Brass,Bronze ,

Stainless steel: 303,304, 316.

Plastic:Delrin,Neoflon®,Nylon,Phenolic Resin,PTFE,PC,ABS.

Secondary Services Offered:laser engraving LOGO.Anodizing,Plating Chrome,Nickel,RoHS Zin,Etc.Assembly Welding,Heat Treating,Powder Coating,Centerless Grinding.

Fast delivery is our advantage, CNC Turning parts, 3 days to complete the sample, and can be listed according to the work plan to provide emergency expedited service, the fastest sample to complete one day.The factory provides 2 ~ 3 sets of CNC Turning Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day.

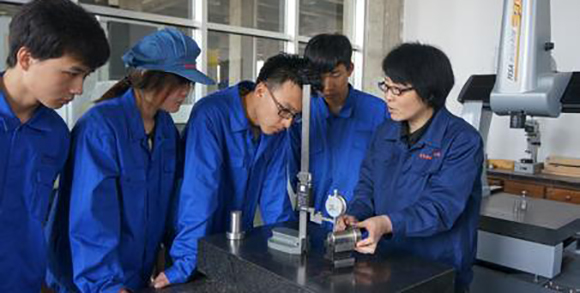

We can provide high-quality mechanical turning parts, from our high-precision machinery and equipment, strict quality control processes, humane management, excellent team..Our technical staff for each CNC machinng turning drawing based on the material of the product for detailed analysis. Reasonable set for the machine parameters. Including: cutting (machining) speed (linear speed, circumferential speed). Tool material. Processing conditions (roughing machining and finishing machining turning). Feed amount. Cutting (turning) depth.

Our engineers focus on continuously improving CNC turning technology.A comprehensive understanding and master the CNC turning and CNC Milling programming the basic process and key technologies.Proficiency in the use of CAD / UG / Master CAM software on the important processing procedures should be CNC Machining Turning test.

CNC Machining can import your Para-Solid 3D image files, .PDF and IGES,STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

You send the drawings to our mailbox, we will reply you as soon as possible, sample production completed within a week.

Product Categories : CNC Machining Turning

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.