Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

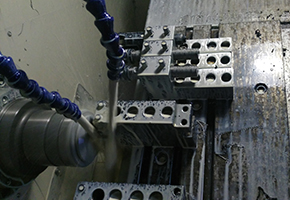

Model No.: TU-017

Finish: NA

Tolerance: 0.015mm

Sample Lead Time: 3 Day

Material: Stainless Steels 303

Product Size(mm): ф16*22

Productivity: 540000/Month

Transportation: Ocean,Land,Air

[]

Our small turn part is the smallest size:ф0.5*1mm. CNC Turning center in processing small turning parts, spindle speed 3000RPM.

Our CNC Turning Center is equipped with a multi-station turret or power turret. The machine has a wide range of processing performance, Machinable linear cylinder, diagonal cylinder, arc and a variety of thread, groove, worm and other complex parts. The cnc turnining and CNC Milling Machining materials are: Aluminum 6061,6063,6061-T6,7075,5052.2017.6082.

Alloy Steels,Carbon Steel,

Brass,Bronze ,

Stainless steel: 303,304, 316.

Plastic:Delrin,Neoflon®,Nylon,Phenolic Resin,PTFE,PC,ABS.

Secondary Services Offered:laser engraving LOGO. Anodizing,Plating Chrome,Nickel,RoHS Zin,Etc. Assembly Welding, Heat Treating, Powder Coating, Centerless Grinding. Can be CNC Machining Turning : Auto Parts, Robot Parts, bushings, Shift knobs, Motorcycle Parts, Toy Parts, Knobs, Pulleys, shafts, hubs, Drone parts, flywheels, etc.

We focus on short-term delivery, commitment to provide samples a week. For a simple CNC Turning parts, complete the sample in 3 days.The factory provides 2 ~ 3 sets of CNC Turning Center for sample production.The workers were divided into two groups to ensure that the machines were produced 24 hours a day.In order to meet these services, we also have a qualified supplier base,So that we can provide products from the surface to the parts LOGO mark the integrity of the quality of cnc turning services..

We provide CNC Machining turning prarts that meet the performance, quality, reliability, and safety requirements of our customers.And the design of reasonable detection fixture to ensure more efficient testing.

ISO9001:2008 quality system runs through every department.We obtain the best quality of the products from the following points:The accuracy of the equipment. To meet the product quality of the CNC Machining turning processing technology, The choice of tools and a reasonable auxiliary fixture. Training of workers. CNC lathe parts processing of each link detection.

A specialized CNC machining turning technology team ,These are: 8 with more than 10 years of work experience in programming, 12 more than 8 years of skilled workers. Regularly from the famous CNC machining technology schools to recruit professional talents.And will ask the CNC machining industry's leading engineers to the factory on-site guidance.

CNC Machining can import your Para-Solid 3D image files . PDF and IGES,STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : CNC Machining Turning

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.