Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

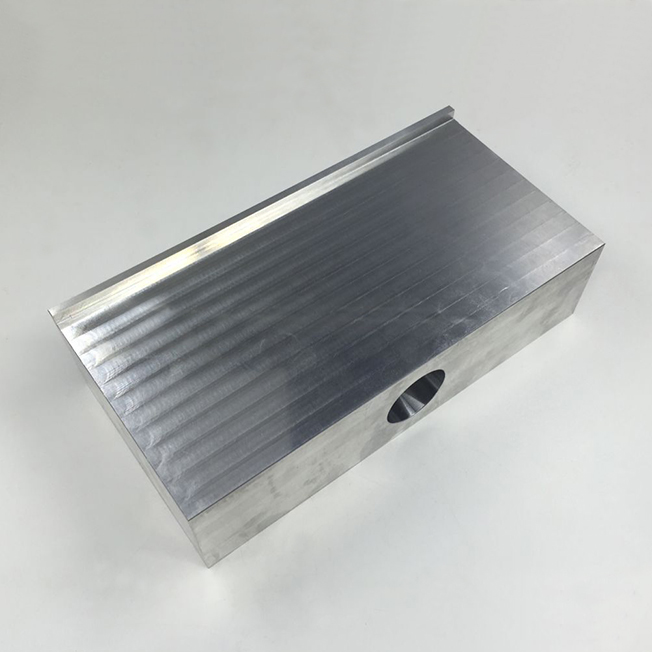

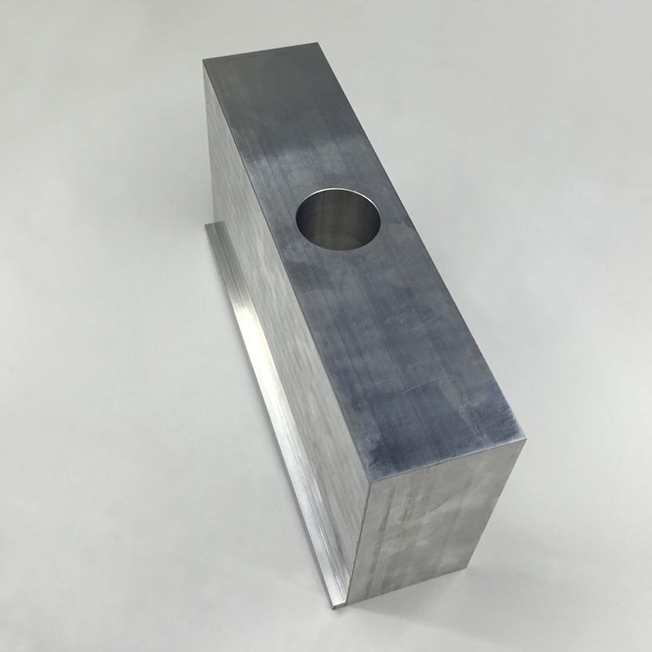

Model No.: CM-037

Tolerance: 0.01mm

Material: Aluminum 6061

Finish: NA

Sample Lead Time: 6 Days

Product Size(mm): 182*105*62

Productivity: 2600/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

Milling Aluminum block is the process of Machining a block of aluminum blank into a product through a milling machine. In the milling aluminum block process, the loading and unloading of aluminum block should be fast, convenient and reliable, so as to shorten the stop time of the machine; The parts on the fixture shall not prevent the machine tool from machining the surface of the aluminum block, that is, the fixture should be opened and its positioning and clamping elements can not affect the knife in the process. after milling aluminum block, the mechanical, physical and chemical properties of the surface layer are different from those of machined aluminum blocks, the representation are work hardening, residual stress generation, fatigue strength and corrosion resistance decreased, and these will directly affect the use performance of machined aluminum blocks.

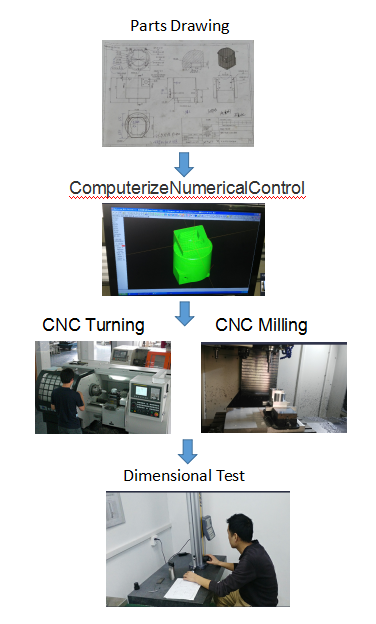

CNC Machining including CNC Milling and CNC Turning, cutting, grinding, milling, Sheet Metal Fabrication.

CNC Milling Machining and CNC turnining materials are:

Aluminum: 6061, 6063, 6061-T6, 7075, 5052, 2017, 6082.

Steel: Q235, 45#, A3, 718H, S136, SKD11.

Stainless steel: SUS303, SUS304, (1.4301), SUS316.

copper / brass / bronze.

Plastic: POM, Teflon, PA, ( PA66 ) PC, PMMA, Delrin, Nylon etc..

Product surface treatment: anodize (clear, black, blue, yellow, can also customize a variety of colors), Sandblasting, spraying, Passivation, laser engraving LOGO, silk screen LOGO.

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. And through the ISO 9001: 2008 quality certification system, the production base is located in Shenzhen bright. CNC machining plant covers an area of over 2,600 square meters, the main production of CNC Machining Parts for medical, automotive, communications, electrical, electronics and other industries. Production types include CNC milling, CNC turning, grinding, stamping, bending, welding, die casting, drilling, tapping and injection molding. More than 46 CNC machining centers and CNC lathes for your service.

We offer industry-leading custom CNC turning and milling. Our precision parts serve medical, communications, aerospace, drone, and robots. Providing the best CNC turning and CNC horizontal / vertical milling. Our extensive range of state-of-the-art CNC lathes and CNC Turning machines meet the tolerances of ± 0.01mm.

Fast delivery is our advantage, CNC Machining Parts, 3 days to complete the sample, and can be listed according to the work plan to provide emergency expedited service, the fastest sample to complete one day. The factory provides 2 ~ 3 sets of CNC machining Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : CNC Milling Machining

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.