Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

"Maximizing Efficiency and Quality Through Precision CNC Milling"

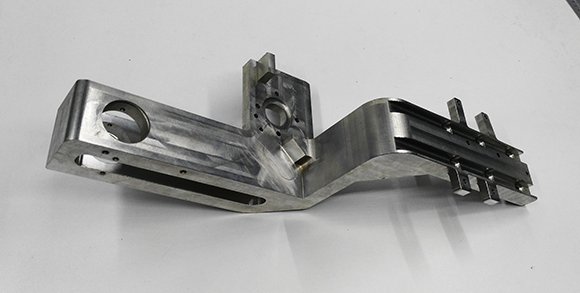

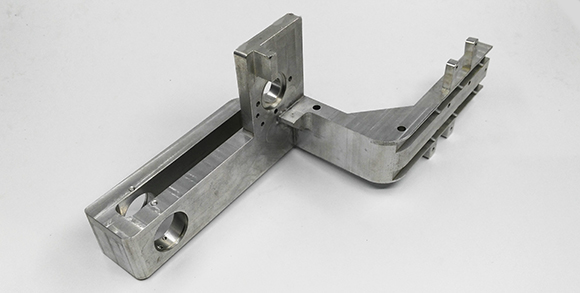

Model No.: CM-007

Tolerance: 0.01mm

Material: Aluminum 6061-T6

Finish: Clear Anodize

Sample Lead Time: 8 Days

Product Size(mm): 240.2*92*50.8

Productivity: 500/Month

Transportation: Ocean,Land,Air

[]

A Precision CNC Milling Machining parts, used in conjunction with large machines. Each face of the product should be machined, the workpiece size tolerance 0.02mm. We organized a special technical staff on the Special Machining Parts programming, set up each cutting step, cutting the amount of spindle speed. A new product in the whole process of mechanical processing quality control, and the emergence of various adverse factors to solve, we established a smooth communication channels, the first time and customers get in touch. 1: Factory Size: 2600 square meters construction plant, has passed ISO9001: 2008 quality system certification. 2: We have 46 CNC machines, including: CNC Machining center, CNC Lathe, Drill Press, lathe, Milling Machine. We have processed thousands of parts in many different industries, including aerospace and medical, Man-machine, UAV and robot parts Quality control:

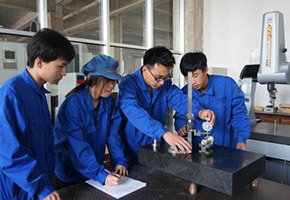

3: IPQC for each product processing steps to detect, and the first 100% full-size product testing. The FQC inspects the product before shipment and reports the shipment. Our inspection tools are: Digital caliper, Micrometer Calipers, height gauge, Profile projector. . . Tolerances can be measured +/- 0.001mm.

From the procurement of raw materials to CNC Machining Parts shipments, we have established a complete set of quality control system.The whole process of operating workers by SOP operations, IPQC products for each processing steps to detect,Make sure the product meets the requirements before proceeding to the next CNC Milling Machining.And 100% full-size inspection of the first machining part. FQC tests the product before shipping and ships the shipping report. Engineering and technical personnel on a regular basis for processing and maintenance settings, timely update processing tool. Our inspection tools are:Digital caliper, Micrometer Calipers , height gauge ,Profile projector.Tolerances can be measured +/-0.01mm and 0.001mm.

Our delivery is fast and one week to submit samples of cnc milling machining parts.The raw material purchase of the CNC machining Parts is completed in one day.And we cooperate with the machining tool manufacturers and product surface treatment manufacturers can be in 1 to 2 days to provide our needs.Factories have more than 46 sets of CNC machinery and equipment, and there are plans to purchase new CNC machines.In order to ensure the delivery of milling machining parts ,Our workers are on a 24-hour shift. A professional customer service and customer docking.

Product Categories : CNC Milling Machining

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.