Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

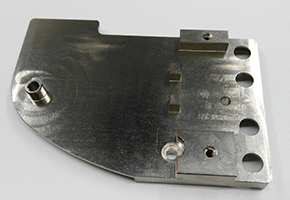

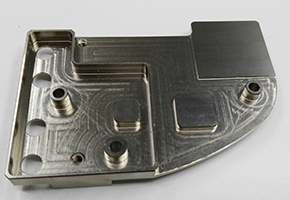

Model No.: CM-004

Tolerance: 0.02mm

Sample Lead Time: One Week

Finish: NA

Material: Titanium TC4

Product Size(mm): 70*49*8

Productivity: 26000/Month

Transportation: Ocean,Land,Air

[]

Titanium alloy CNC Machining used in the cutting fluid, tool materials, tool geometry and processing parameters are stringent requirements. CNC Machining Titanium in the past, we accumulated a wealth of experience, have a dedicated technical workers. In the machining Titanium processing, specializes in the numerical control machining efficiency and economy.

The processing principles are as follows.

1) The choice of a reasonable tool material for titanium alloy material properties, processing methods, processing technology conditions, the rational choice of tool materials. Tool material should be selected good wear resistance, high hot hardness, and has sufficient toughness of the material.

2) To improve the cutting conditions: machine / fixture / tool system rigidity is better. The gap between the various parts of the machine to be adjusted, the spindle radial beating to be small. Clamping fixture workpiece to be strong, should have sufficient rigidity. Cut part of the tool as short as possible, in the case of adequate chip to maximize the cutting edge thickness, improve the strength and rigidity of the tool.

3) A reasonable processing technology, CNC machining in the titanium medium-range, the use of reasonable processing technology is very important, CNC Milling Machining Titanium Parts which part of the first processing, which part must be set up after processing. So that the smooth progress of cutting, access to reasonable processing quality and efficiency.

4) Select a reasonable cutting rate, cutting speed should be low. Because the cutting speed on the temperature of the cutting edge of a great cutting depth to be large. Experiments show that the cutting depth of the blade temperature is less affected, so a lower cutting speed, increasing the cutting depth of the titanium alloy cutting is beneficial, especially when roughing, to ensure that the tool completely into the surface of the titanium alloy is being cut , In order to prevent the occurrence of wear or chipping phenomenon. Cutting process can not stop the knife. In CNC Milling Machining Titanium to stop the knife will be under high load for a long time friction, easy to cause titanium alloy work hardening, resulting in sintering and cracking and damage to the tool.

Our team provides technical services for the CNC machining titanium Parts

Milling Machining titanium alloy to increase the impact of cutting fluid strength, used to cool the tool.

CNC Milling Machining Titanium Parts

A specialized CNC machining technology team ,These are: 8 with more than 10 years of work experience in programming, 12 more than 8 years of skilled workers.. Regularly from the famous CNC machining technology schools to recruit professional talents.And will ask the CNC machining industry's leading engineers to the factory on-site guidance.

You send the drawings to our mailbox, we will reply you as soon as possible, sample production completed within a week. CNC Machining can import your Para-Solid 3D image files, .PDF and IGES,STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : CNC Milling Machining

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.