Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

"Exceeding Expectations: Our Custom Precision Turning Services Deliver Unmatched Quality and Accuracy"

Model No.: TU-042

Tolerance: 0.01mm

Material: Aluminum 6061

Finish: NA

Sample Lead Time: 6 Days

Product Size(mm): ф21.3*80

Productivity: 2600/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

The basic content of Custom metal turning is mainly to process parts with rotating surfaces. Custom metal turning has a wide range of Machining. Custom metal turning can turning cylindrical, end face, cut groove and cut off, drill center hole, drill hole, turning hole, reaming, turning various kinds of thread, turning circular cone surface, turning forming surface, knurling and coiled spring, etc., if you attach other accessories and fixtures on the lathe, drilling, grinding, lapping, polishing, and machining of round, inner holes of various complex shapes can also be carried out. On a horizontal lathe of ordinary accuracy, the machining accuracy of the excircle surface can be up to IT7 ~ IT6, the surface roughness can reach 1.6~1.8 μm. Therefore, custom metal turning play a very important role in the machine manufacturing industry.

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. Our CNC Milling Machining and CNC Turning materials are:

| Aluminum | 6061, 6061-T6, 6063, 7075, 5052, 2024, 2017, 6082 |

| Copper | Copper, Brass, Bronze |

| Stainless Steel | SUS303, SUS304, (1.4301), SUS316 |

| Steel | Q235, 45 #, A3, 718H, S136, SKD11 |

| Titanium | |

| Plastic | Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, PMMA, PC, PAI, PPS, PA, PVDF, POM, PA, PET, PEI |

In addition, we also offer products for your secondary processing services: anodize (clear, black, blue, yellow, can also customize a variety of colors), Sandblasting, spraying, Passivation, laser engraving LOGO, silk screen LOGO.

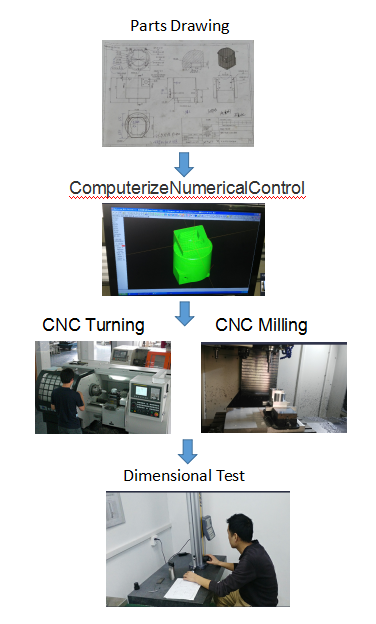

Powerful CNC Machining Turning technical team is to ensure that the basis of product quality, Our engineers focus on continuously improving CNC turning technology. A comprehensive understanding and master the CNC turning and CNC Milling programming the basic process and key technologies. Proficiency in the use of CAD / UG / Master CAM software on the important processing procedures should be CNC Machining turning test.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Our characteristics:

Product Categories : CNC Machining Turning

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.