Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

Model No.: TU-007

Tolerance: 0.02mm

Sample Lead Time: 3 Days

Material: Aluminum 6061

Finish: Blue Anodize

Product Size(mm): ф40*20.5

Productivity: 52000/Month

Transportation: Ocean,Land,Air

[]

This CNC lathe turning components is made of 6061 aluminum alloy. According to customer's requirements, we have made two different blue anodize surface treatments for CNC lathe turning components. Machining process: CNC Turning and CNC cutting, first turning, then rough and finish machining, according to the size tolerance of drawings, also need to do some auxiliary fixtures to help the machining process. In addition, the effect of surface treatment by anodize oxidation on the size of CNC lathe turning components must be taken into account.

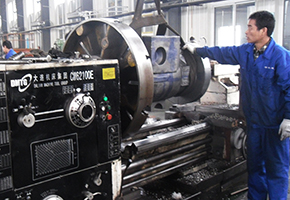

Our CNC Turning Center is equipped with a multi-station turret or power turret. The machine has a wide range of processing performance, Machinable linear cylinder, diagonal cylinder, arc and a variety of thread, groove, worm and other complex parts As well as six lathe. Processing size of the largest diameter can reach ф860mm, a single product the thinnest 0.23mm cnc turnining and CNC Milling Machining materials are: copper / bronze / H62,

Titanium / TC4

Aluminum 6061,6063,6061-T6,7075,5052.2017.6082.

Stainless steel: 303,3041, 316 ,

Steel: Q235,45 #, A3, 718H, S136, SKD11

Plastic: POM,PA,(PA66) PC,PMMA. Product surface treatment: anode (clear,black, blue, yellow, can also customize a variety of colors).Sandblasting, spraying, Passivation, laser engraving LOGO, silk screen LOGO.

Our engineers focus on continuously improving CNC turning technology.A comprehensive understanding and master the CNC turning and CNC Milling programming the basic process and key technologies.Proficiency in the use of CAD / UG / Master CAM software on the important processing procedures should be CNC Machining Turning test..

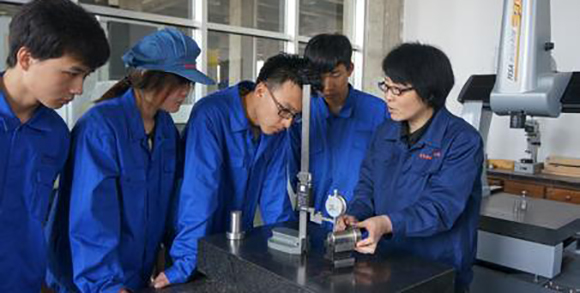

Each piece of the CNC Machining turning parts is rigorously tested three times,First Article Inspection,Process inspection.Final inspection.The inspection work and CNC turning process control in close connection.The quality of each process or the possible quality problems left off.Reject the unqualified product, so that it can not be put into the sequence or factory, so as to achieve the purpose of process control

The variety of our precision machining centers allows us to offer our customers the best prices for producing custom machined parts. Regardless of the size or specification of your order, we have the equipment that can to do the job right and produce your parts when and how you need them.

CNC Machining can import your Para-Solid 3D image files, .PDF and IGES,STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : CNC Machining Turning

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.