Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

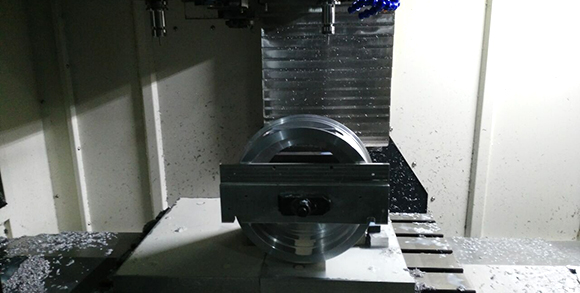

Model No.: SS-030

Material: Stainless Steel 303

Tolerance: 0.01mm

Sample Lead Time: 3 Days

Finish: NA

Product Size(mm): ф20*18

Productivity: 7800/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

In the Machining 303 stainless steel parts process will inevitably produce stress such as casting stress, cold deformation stress, welding stress, machining stress, heat treatment stress, working stress in the working condition of 303 stainless steel parts, and thermal stress caused by temperature gradient and so on. These stresses all may become the stress factors of stress corrosion cracking. When corrosion medium contains ions and molecules which have special effects on stress corrosion cracking, it will lead to stress corrosion cracking. For 303 stainless steel parts, the medium that causes stress corrosion cracking includes aqueous solution medium contains Cl-, F-, Br- and H₂S, NaOH, saturated SO₂ and so on, such as acidic chloride solution, seawater, high temperature alkali, nitric acid, sulfuric acid, hydrochloric acid, chloride containing condensate water and high temperature water and so on. For stainless steel turned parts, if the surface has a stable passive film and can be repaired quickly after damage, then stainless steel turned parts will more advantageous to resist stress corrosion cracking.

As a custom CNC Machining shop, we machine specialty parts out of any specified material, from standard to exotic.

| Aluminum | 6061, 6061-T6, 6063, 7075, 5052, 2024, 2017, 6082 |

| Copper | Copper, Brass, Bronze |

| Stainless Steel | SUS303, SUS304, (1.4301), SUS316 |

| Steel | Q235, 45 #, A3, 718H, S136, SKD11 |

| Titanium | |

| Plastic | Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, PMMA, PC, PAI, PPS, PA, PVDF, POM, PA, PET, PEI |

In addition, we also offer products for your secondary processing services: Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing.

Fast delivery is our advantage, CNC Turning parts, 3 days to complete the sample, and can be listed according to the work plan to provide emergency expedited service, the fastest sample to complete one day. The factory provides 2 ~ 3 sets of CNC Turning Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day.

The variety of our precision machining centers allows us to offer our customers the best prices for producing custom machined parts. Regardless of the size or specification of your order, we have the equipment that can to do the job right and produce your parts when and how you need them.

Product Categories : Machining Stainless Steel

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.