Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

Model No.: SS-021

Tolerance: 0.02mm

Material: Stainless Steel 304

Sample Lead Time: 3 Days

Finish: Passivation

Product Size(mm): 158*1.6.5

Productivity: 7800/Month

Transportation: Ocean,Land,Air

[]

Stainless steel is for the purpose of improving the corrosion resistance and hardness, contain a single element of chromium or chromium, nickel two kinds of elements of the alloy Steel. In general, chromium content of more than 10.5% of the alloy can be called "stainless steel", through chromium on the surface of steel to form a thin oxide film to improve the corrosion resistance of steel. Good corrosion resistance, not easy to rust means that the surface of the product is not required to be electroplated or painted. Stainless steel parts containing 13% chrome is used in situations where hardness requirements are higher than rust resistance, such as bolts, nuts, knives, forks, cutlery, etc. that require high hardness. Stainless steel parts containing 18% chromium is used in situations where high rust resistance is required, such as cooking machines, automotive parts, chemical plants, and the like. Stainless steel parts containing 18% chromium and 8% nickel is not only good corrosion resistance, but also tensile strength, is used in the cars, railways and other structural parts, and as a building material and widely used.

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. And through the ISO 9001: 2008 quality certification system, the production base is located in Shenzhen bright. CNC Machining plant covers an area of over 2,600 square meters, the main production of CNC Machining Parts for medical, automotive, communications, electrical, electronics and other industries. Production types include CNC Milling,CNC Turning, grinding, stamping, bending, welding, die casting, drilling, tapping and injection molding. More than 46 CNC machining centers and CNC lathes for your service.

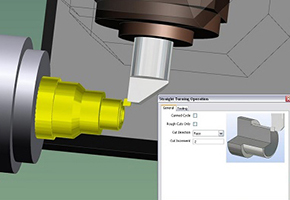

Powerful CNC Milling Machining technical team is to ensure that the basis of product quality,Our engineers focus on continuously improving CNC milling technology.A comprehensive understanding and master the CNC turning and CNC milling programming the basic process and key technologies.Proficiency in the use of CAD / UG / Master CAM software on the important processing procedures should be CNC Machining Turning test.

We focus on short-term delivery, commitment to provide samples a week. For a simple CNC Turning parts, complete the sample in 3 days.The factory provides 2 ~ 3 sets of CNC Turning Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day.In order to meet these services, we also have a qualified supplier base.So that we can provide products from the surface to the parts LOGO mark the integrity of the quality of cnc turning services.

CNC Machining can import your Para-Solid 3D image files, .PDF and IGES,STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.You send the drawings to our mailbox, we will reply you as soon as possible, sample production completed within a week.

Produce image:

Product Categories : Machining Stainless Steel

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.