Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

Model No.: SS-027

Tolerance: 0.02mm

Material: Stainless Steel 304

Sample Lead Time: 3 Days

Finish: NA

Product Size(mm): 45*45*15

Productivity: 4600/Month

Transportation: Ocean,Land,Air

[]

When Machining Stainless Steel metal parts, the geometry of the cutting part of the tool should be considered in terms from the choose of the front angle and the back angle. In the choice of rake angle, to consider the chip flute type, with or without chamfering and blade angle of positive and negative angle size and other factors. No matter what kind of tool, stainless steel metal parts must be machined by larger front angles. Increasing the rake angle of the tool reduces the resistance encountered in the process of chip removal and clearance. The rear corner of the selection requirements are not very strict, but not too small, if the rear angle is too small, will easy to cause serious friction with the workpiece surface, so that the deterioration of the surface roughness of processing, accelerated tool wear. And due to the strong friction, enhanced the effect of hardening of the surface of stainless steel metal parts; The tool rear angle should not be too large, the rear angle is too large, so that the wedge angle of the tool decreases, reducing the strength of the cutting edge to accelerate the wear of the tool.

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. We offer industry-leading custom CNC Turning and milling. Our precision parts serve medical, communications, aerospace, drone, and robots. Providing the best CNC turning and CNC horizontal / vertical milling. Our extensive range of state-of-the-art CNC lathes and CNC Turning machines meet the tolerances of ± 0.01mm. We guarantee the best quality materials and the best processing of technology to meet your needs.

Our CNC Milling Machining and CNC turning materials are:

| Aluminum | 6061,6061-T6,6063,7075,5052,2024,2017,6082 |

| Copper | Copper,Brass,Bronze |

| Stainless Steel | SUS303, SUS304, (1.4301), SUS316 |

| Steel | Q235,45 #, A3, 718H, S136, SKD11 |

| Titanium | |

| Plastic | Delrin,Nylon,Neoflon,PTFE,Teflon,Ultem,Torlon,Peek,PMMA,PC,PAI,PPS,PA,PVDF,POM,PA,PET,PEI |

In addition, we also offer products for your secondary processing services: anodize (clear,black, blue, yellow, can also customize a variety of colors), Sandblasting, spraying, Passivation, laser engraving LOGO, silk screen LOGO.

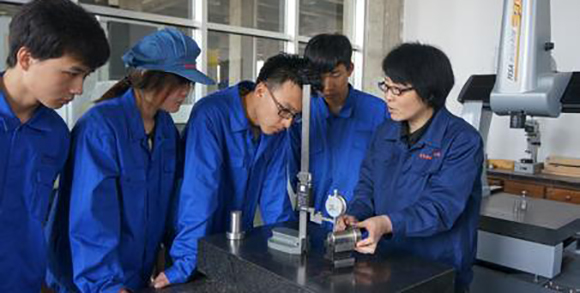

We have a specialized CNC Machining technology team, These are: 8 with more than 10 years of work experience in programming, 12 more than 8 years of skilled workers. Regularly from the famous CNC machining technology schools to recruit professional talents. And will ask the CNC machining industry's leading engineers to the factory on-site guidance.

Fast delivery is our advantage, CNC Machining Parts, 3 days to complete the sample, and can be listed according to the work plan to provide emergency expedited service, the fastest sample to complete one day. The factory provides 2 ~ 3 sets of CNC machining Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : Machining Stainless Steel

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.