Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

Model No.: CU-059

Material: Copper

Tolerance: 0.01mm

Sample Lead Time: 3 Days

Finish: NA

Product Size(mm): 15*13*12

Productivity: 4800/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

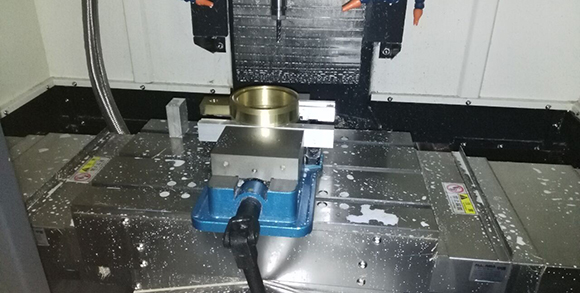

CNC Milling Machining Copper Components

The milling cutter used for milling Machining copper is mainly made of high-speed steel and K-type hard alloy. When milling machining copper and other materials with large plasticity, low hardness, large cutting deformation and easy to stick, the cutting edge of the milling cutter must be sharp, i.e. the front angle should be large, and it is better to grind a large arc chip groove on the front cutter face; the surface roughness values of the front, back and cutting edge of the milling cutter should be small. When high-speed steel milling cutter is used to milling machining copper, the front angle is generally 20-35 degrees; the back angle is 12-25 degrees; the main deflection angle is 45-90 degrees; the secondary deflection angle should be larger, generally 5-10 degrees. If K-type carbide milling cutter is used to milling machining copper, the rake angle should be slightly smaller than that of high-speed steel milling cutter.

We provide CNC Machining Copper for contacts that meet the performance, quality, reliability, and safety requirements of our customers. And the design of reasonable detection fixture to ensure more efficient testing.

We offer industry-leading custom CNC Machining copper for contacts. Our beryllium copper battery contacts serve medical, communications, aerospace, drone, and robots. Providing the best CNC Turning and CNC horizontal / vertical milling. Our extensive range of state-of-the-art CNC lathes and CNC turning machines meet the tolerances of ± 0.01mm.

We have three types of machining copper: copper, brass, bronze.

CNC Machining Beryllium Copper including CNC Milling and CNC turning, cutting, grinding, milling, Sheet Metal Fabrication. CNC milling machining and CNC turnining materials are: Aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6082. Steel: Q235, 45#, A3, 718H, S136, SKD11. Stainless steel: SUS303, SUS304,( 57529418, 55101211, 54084236,1.4301), SUS316. Brass/ copper / bronze. Plastic: POM, Teflon, PA,( 57529419, 55101212, 54084237,PA66) PC, PMMA. Product surface treatment: anodiza (clear, black, blue, yellow, can also customize a variety of colors), sandblasting, spraying, passivation, laser engraving LOGO, silk screen LOGO.

CNC Machining copper for contacts can import your Para-Solid 3D image files, PDF and IGES, STEP or X-T files. Please send in your 3d work and PDF for a quote.

Product Categories : Machining Copper

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.