Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

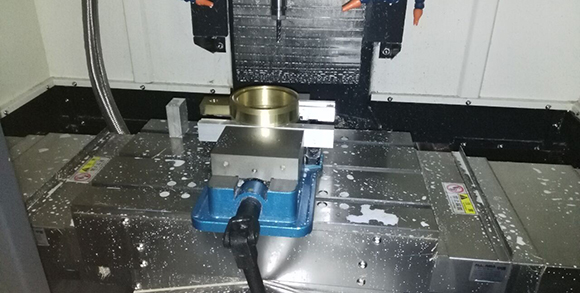

Model No.: CU-040

Material: Copper

Tolerance: 0.01mm

Sample Lead Time: 3 Days

Finish: NA

Product Size(mm): Ф85*16

Productivity: 4800/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

Machining Copper Tube Services

The yield strength of copper is very high, but the elongation is low. In order to increase or reduce the hardness of the copper material at Machining copper tube, the copper hardness will be changed by heat treatment of copper. In machining copper tube, because of the high plasticity and toughness of copper, poor chip breaking performance and serious sticking knife, so the machining property is poor. Especially when turning deep ring groove, it is difficult to solve the problem of the rigidity of the tool bar and the problem of chip removal, so machining copper tube is quite difficult. We have ten years of machining copper tube experience and can solve such problems effectively.

We provide CNC Machining prarts that meet the performance, quality, reliability, and safety requirements of our customers. And the design of reasonable detection fixture to ensure more efficient testing.

We offer industry-leading custom CNC Turning and milling. Our precision parts serve medical, communications, aerospace, drone, and robots. Providing the best CNC turning and CNC horizontal / vertical milling. Our extensive range of state-of-the-art CNC lathes and CNC turning machines meet the tolerances of ± 0.01mm.

We have three types of machining copper: copper, brass, bronze.

CNC machining including CNC Milling and CNC turning, cutting, grinding, milling, Sheet Metal Fabrication. CNC Milling Machining and CNC turnining materials are: Aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6082. Steel: Q235, 45#, A3, 718H, S136, SKD11. Stainless steel: SUS303, SUS304, (1.4301), SUS316. Brass/ copper / bronze. Plastic: POM, Teflon, PA, (PA66) PC, PMMA. Product surface treatment: anodiza (clear, black, blue, yellow, can also customize a variety of colors), sandblasting, spraying, passivation, laser engraving LOGO, silk screen LOGO.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : Machining Copper

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.