Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

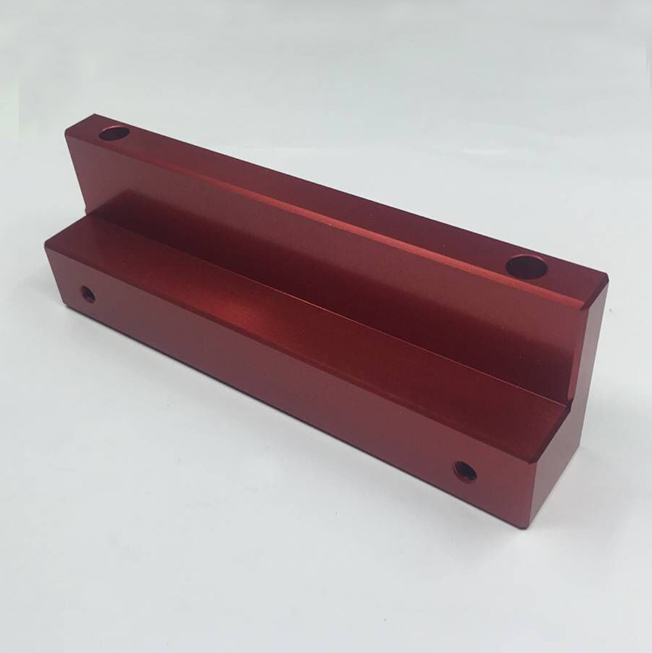

Model No.: AL-090

Tolerance: 0.01mm

Sample Lead Time: 3 Days

Material: Aluminum 6061

Machining Processes: CNC Milling

Finish: Anodized Red

Product Size(mm): 145*50*29

Productivity: 7800/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

With the continuous development of aluminum products Machining industry, in the industry more and more widely used red anodized aluminum method, form a layer of oxide film on the surface of aluminum and Aluminum Alloy parts, in order to achieve the purpose of protection and decoration. The oxide film of Red anodized aluminum parts consists of a large number of hexagonal cells perpendicular to the surface of the metal, each cell has a film hole in the center and has a strong adsorption force, the chemical coloring of red anodized aluminum parts oxide films is based on the ability of the porous membranes to adsorb dyes, such as textile fibers. Red anodized aluminum is widely used in coloring interior decoration, daily use of small aluminum products etc..

We have a dedicated CNC Machining technology team. Actory processes: order review, drawing review, product CNC programming, production planning, processing, quality inspection, packaging and transportation. Our technical staff in the plastic machining processing has accumulated a lot of technical experience, detailed analysis of the product deformation in the Machining Plastic is given. Almost all workers in the plastic processing process will be manufactured to help the fixture inhibit deformation of the product.

| Business content | CNC miliing, CNC Turning |

| Machining Processes | CNC Milling , CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

| Machining Metal | Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

| Parts Size | Milling Parts ( MAX) : Length 1030mm,Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm,Length 750mm. |

| Tolerance | 0.01mm |

| Equipment Capabilities | CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

| Secondary Services of Machining Parts | Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

| Sample | Samples are for free, sample time is 5 days. |

| Delivery | Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

| file format | Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

We are looking forward to further contact with you. Have a nice day and thanks for your inquiry!

Product Categories : Machining Aluminum

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.