Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

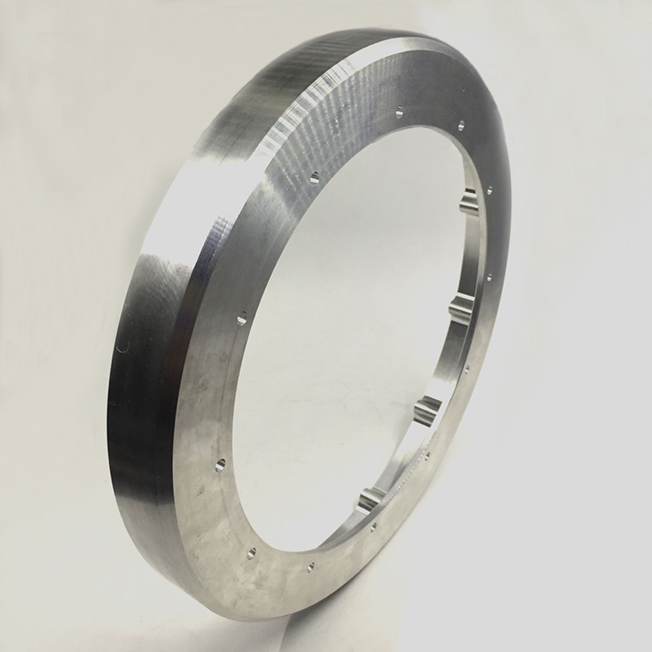

Model No.: AL-046

Tolerance: 0.02mm

Material: Aluminum 6061

Finish: NA

Sample Lead Time: 6 Days

Product Size(mm): ф310*37

Productivity: 2600/Month

Transportation: Ocean,Land,Air

[]

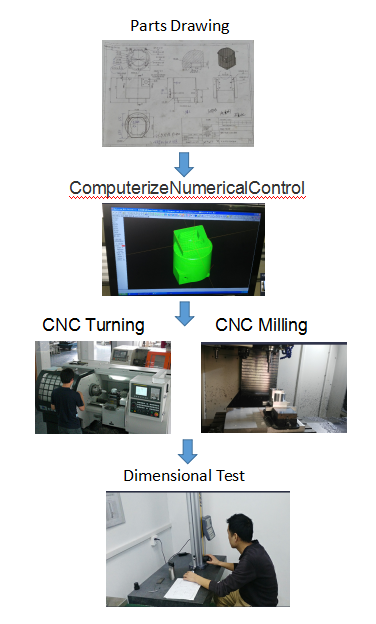

The cutting movement of the turning Machining process is circumferential and the movement of the cutter is linear. The combined movement of the two movements enables the turning machining process to proceed continuously. According to the different direction of movement, turning is divided into two categories: peripheral turning and face turning. In peripheral turning, the direction of tool feed motion is parallel to the workpiece direction. The composite of the two motions produces a peripheral surface. The reduction of the blank diameter is two times of the cutting depth, and the cutting speed is constant. The end face turning is the direction of the tool feed movement is perpendicular to the workpiece direction. The composite of the two movements produces the end face. And the reduction in the length of the blank is equal to the cutting depth. When the number of revolutions of the workpiece is constant, the cutting speed decrease continuously, and the value of the cutting speed becomes zero when the workpiece center is reached.

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. And through the ISO 9001: 2008 quality certification system, the production base is located in Shenzhen bright. CNC machining plant covers an area of over 2,600 square meters, the main production of CNC Machining Parts for medical, automotive, communications, electrical, electronics and other industries. Production types include CNC Milling,CNC Turning, grinding, stamping, bending, welding, die casting, drilling, tapping and injection molding. More than 46 CNC machining centers and CNC lathes for your service.

Our CNC Milling Machining and CNC turning materials are:

| Aluminum | 6061,6061-T6,6063,7075,5052,2024,2017,6082 |

| Copper | Copper,Brass,Bronze |

| Stainless Steel | SUS303, SUS304, (1.4301), SUS316 |

| Steel | Q235,45 #, A3, 718H, S136, SKD11 |

| Titanium | |

| Plastic | Delrin,Nylon,Neoflon,PTFE,Ultem,Torlon,Peek,PMMA,PC,PAI,PPS,PA,PVDF,POM,PA,PET,PEI |

In addition, we also offer products for your secondary processing services: anodize (clear,black, blue, yellow, can also customize a variety of colors), Sandblasting, spraying, Passivation, laser engraving LOGO, silk screen LOGO.

Powerful CNC Machining Turning technical team is to ensure that the basis of product quality, Our engineers focus on continuously improving CNC turning technology. A comprehensive understanding and master the CNC turning and CNC milling programming the basic process and key technologies. Proficiency in the use of CAD / UG / Master CAM software on the important processing procedures should be CNC Machining turning test.

CNC Machining can import your Para-Solid 3D image files, .PDF and IGES,STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : Machining Aluminum

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.