Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

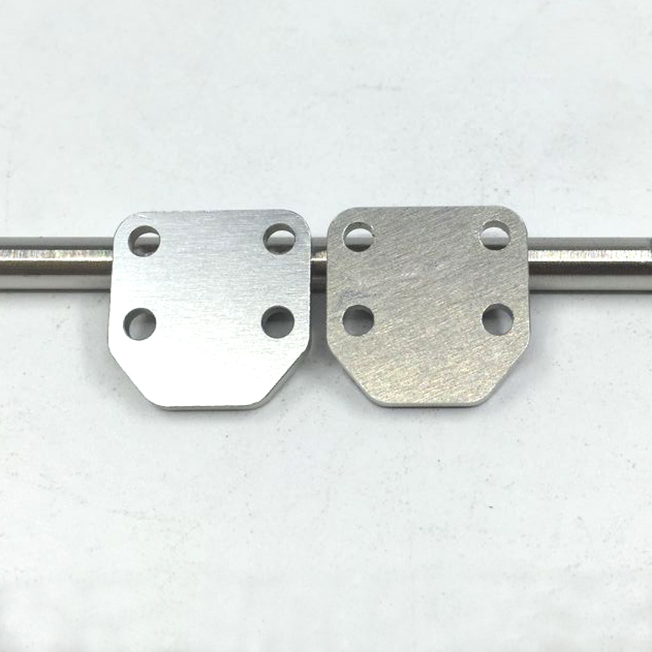

Model No.: AL-040

Tolerance: 0.01mm

Material: Aluminum 6061

Sample Lead Time: 5 Days

Finish: Nickel Plating

Product Size(mm): 25*23*2

Productivity: 4600/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

Bright Nickel Plating on Aluminum Parts

In recent ten years, the development and application of bright nickel plating aluminum process, high decorative heavy protective multi-layer nickel chromium process, black nickel, sand nickel, longhole nickel is developing rapidly, is a hot topic in the electroplating industry. One of the most important reasons why bright nickel plating has been used so widely is the rapid development of motorcycles, automobiles and other manufacturing industries, the electroplating process of automobile aluminum wheel hub not only promoted the development of bright nickel plating aluminum process, but also promoted the industrialization application of multi-layer Ni Cr system.

Here are some sample for our prouduction:

We provide high-precision Machining services:

1 Machining process: CNC Milling, CNC Turning, Sheet Metal Fabrication.

2 CNC Machining range:

Aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6083.

Steel: Q215, Q235, 10#, 15#, 45#, S136, SKD11, 718H.

Copper / bronze / Titanium / TC4.

Plastic: Delrin POM,Teflon, Nylon, PA, PC, PMMA, Ultem, PEI, PTFE.

Stainless steel: 303, 304, 316, 430, 420.

Secondary Services Offered: laser engraving LOGO. Anodizing, Plating Chrome, Nickel, RoHS Zin, Etc. Assembly Welding, Heat Treating, Powder Coating, Centerless Grinding.

3 CNC machining equipment: CNC machining center, CNC turning center, engine lathe, drill press, milling machine, grind machine.

CNC Machining Product Accuracy 0.005mm.

We use ISO9001:2008 quality system certification to ensure the quality of products. Quality personnel are measuring the size of each piece of machining products, measuring instruments include Digital caliper, Micrometer Calipers, height gauge, Profile projecto, these measuring instruments regularly through the third party laboratory calibration, the measurement accuracy is 0.001mm. In order to improve the speed of the inspection, the engineer designed a precise auxiliary inspection fixture. We can provide the dimensional measurement report of Machining Parts.

From the previous step of the machining process to the next step, we all use the suitable (or customized) PVC box to temporarily store the products. When all the machining steps are completed, each product is packaged in EPE Poam, and the outer packing of the product will be customized for the appropriate carton or wooden box to prevent the product from colliding during transportation to ensure that you use the perfect products. Through teamwork and fruitful communication, we optimize the management process, we attach importance to every customer, to ensure that each CNC Machining Parts of the quality and delivery.

Product Categories : Machining Aluminum

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.