Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

Model No.: AL-197

Tolerance: 0.01mm

Sample Lead Time: 3 Days

Material: Aluminum 6061

Machining Processes: CNC Milling

Finish: Clear Anodise

Product Size(mm): Φ6*10

Productivity: 7800/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

The turned aluminum bike parts are machined by using CNC Turning machine to Machining a whole aluminum bar. Because the whole process of CNC aluminum machining is completed in one clamp, before cutting off, because turned aluminum bike parts are connected with the bottom of the blank aluminum material, the generation of internal stress will not cause the turned aluminum bike parts to have large deformation. The size of precision turned parts for bike remains stable throughout the CNC aluminum machining process. It should be noted that when cutting, the blank material and precision turned parts for bike need to have 0.1mm adhesion on the bottom to ensure that the strength is enough to resist the cutting stress produced in the process of CNC aluminum machining.

Buildre Group Co., Ltd is a professional manufacturer of Precision CNC Machining services for OEM and ODM parts. And have through the ISO 9001: 2008 quality certification system, our workshop is located in Guangming Shenzhen. Our CNC workshop covers an area of more than 2600 square meters, which can produces precisiopn machined aluminum parts for dry block . The parts we produce are used in medical, automobile, telecommunications, electronics and other industries. Welcome to contact us if you need precision CNC machining services.

>>Operation process

1. Contact us with the drawings of your products.

Files formats accepted when clients send us drawing.

3D: Pro/E, UG

2D: Auto CAD

Accepted file format: .igs, .prt, .stp, .x_t, .dxf, .dwg, .pdf, .jpg, .tif, .bmp, .doc, .xls.

2. Receive our offer.

We will send you quotation sheet as soon as possible.

3. Place the orders.

4. Make payments.

5. Engineers write programs for products.

6. Production.

Machining types: CNC Milling, CNC turning, grinding, stamping, bending, welding, die casting, drilling, tapping and injection molding.

CNC machining range:

* Aluminum: 6061, 6063, 6061-T6, 7075, 5052, 2017, 6083.

* Steel: Q215,Q235,10# 15#, 45#, S136, SKD11,718H.

* Copper / brass / bronze.

* Titanium / TC4.

* Plastic: Delrin (POM), Teflon, Nylon, PA, PC, PMMA, Ultem (PEI), PTFE.

* Stainless steel: 303, 304, 316, 430, 420

Surface treatment: laser engraving LOGO, Anodizing, Sandblasting, Plating Chrome, Plating Nickel, RoHS Zin, Assembly, Welding, Heat Treating and so on.

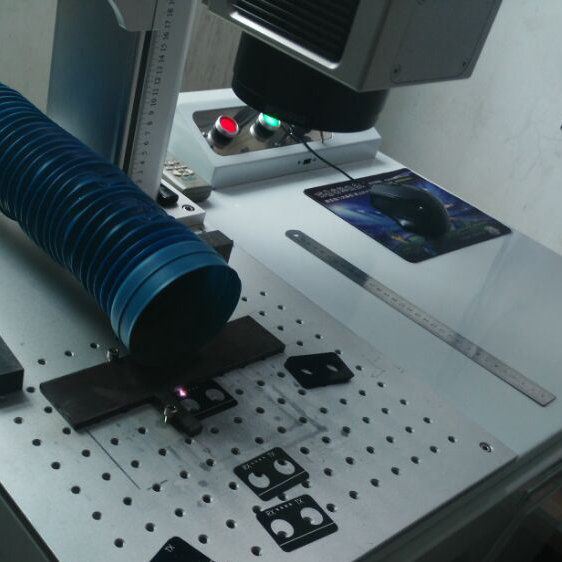

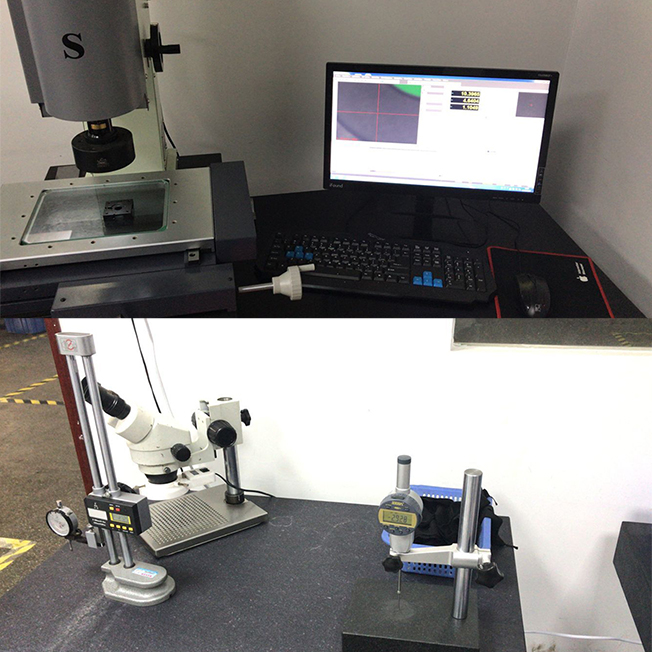

7. QC check the quality of precisiopn machined aluminum parts for dry block .

8. Packing.

9. Delivery.

Within 15-20 workday after payment received.

>>Equipments

CNC milling machines, CNC turning machines

>>Tolerance

Tolerance for the precisiopn machined aluminum parts for dry block : ±0.01mm.

>>Our characteristics

1 Our service is from the provision of technical advice, our engineers will take into account all your requirements to choose the best materials and production processes;

2 We have ample material suppliers to meet the supply of bulk or proofing materials;

3 Our engineers will choose the right tool according to the different nature of the material processing;

4 For easy deformation of the material (nylon, copper, etc.) will have a special process processing;

5 Strict quality management, to ensure the provision of high quality products

Product Categories : Machining Aluminum

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.