Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

Model No.: TU-011

Finish: NA

Tolerance: 0.015mm

Sample Lead Time: 3 Day

Product Size(mm): ф15*20.5

Material: Stainless Steels 316

Productivity: 26000/Month

Transportation: Ocean,Land,Air

[]

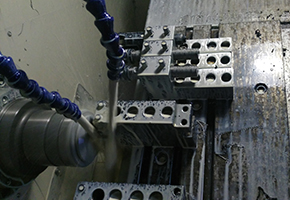

We can provide precision machined products from our high-precision CNC Machining Turning center. Our Machining equipment has the following characteristics:

(1) High precision. Including high precision and static precision, the main performance indicators are spindle rotation accuracy, precision rail movement, sub-degree of precision.They are the foundation to produce CNC precision machined products.

(2) High stiffness. Including the high static stiffness and dynamic stiffness, stiffness itself, the contact stiffness. This is the key to ensure the quality of CNC precision machined products.

(3) High stability. Equipment in the transport, storage, after the use of the provisions of the working environment should be able to maintain a long time precision, interference, stability. Equipment should have good wear resistance, vibration resistance and so on. This is to ensure that the parts of CNC lathe are 100% qualified in batch production.

Our CNC Turning Center is equipped with a multi-station turret or power turret. The machine has a wide range of processing performance, Machinable linear cylinder, diagonal cylinder, arc and a variety of thread, groove, worm and other complex parts. The cnc turnining and CNC Milling Machining materials are: Aluminum 6061,6063,6061-T6,7075,5052.2017.6082.

Alloy Steels, Carbon Steel,

Brass, Bronze ,

Stainless steel: 303,304, 316.

Plastic: Delrin,Neoflon®,Nylon,Phenolic Resin,PTFE,PC,ABS.

Secondary Services Offered: laser engraving LOGO. Anodizing, Plating Chrome, Nickel, RoHS Zin, Etc. Assembly Welding, Heat Treating, Powder Coating, Centerless Grinding. Can be CNC Machining turning : Auto Parts, Robot Parts, bushings, Shift knobs, Motorcycle Parts, Toy Parts, Knobs, Pulleys, shafts, hubs, Drone parts, flywheels, etc.

We attach importance to every customer, every CNC machining Turning drawing. For each drawing will organize a small seminar to arrange the production schedule, technical discussion, process scheduling, quality control point. We focus on the CNC Turning. accumulation of technology, product planning will be held regularly, Review the problems in the machining process, optimize the processing technology, improve the CNC machining quality and efficiency.

Each piece of the CNC machining turning parts is rigorously tested three times, First Article Inspection,Process inspection. Final inspection. The inspection work and CNC turning process control in close connection. The quality of each process or the possible quality problems left off. Reject the unqualified product, so that it can not be put into the sequence or factory, so as to achieve the purpose of process control

A specialized CNC machining turning technology team ,These are: 8 with more than 10 years of work experience in programming, 12 more than 8 years of skilled workers. Regularly from the famous CNC machining technology schools to recruit professional talents. And will ask the CNC machining industry's leading engineers to the factory on-site guidance.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : CNC Machining Turning

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.