Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

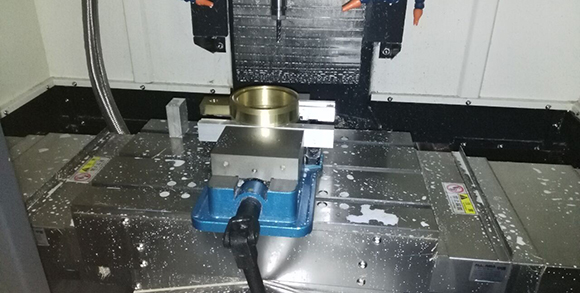

Model No.: CU-058

Tolerance: 0.01mm

Sample Lead Time: 3 Days

Finish: NA

Material: Brass Rod

Product Size(mm): ф30*50

Productivity: 4800/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

Methods to improve the surface quality of brass turning components processed by automatic lathe:

1. Reduce the height of residual area. In turning Machining brass fittings, the height of the residual area can be reduced by reducing the main deflection angle, the secondary deflection angle, the feed rate and increasing the radius of the tool tip arc

2. Avoid the generation of swarf and prick marks. The method of changing cutting speed can be used to restrain the formation of chip accretion when machining brass on a lathe.

3. Avoid wear and bright spots. When machining brass on a lathe, bright spots or bright spots appear on the machined surface, and there is noise when cutting, which indicates that the tool has been seriously worn.And the blunt cutting edge will extrude bright marks on the surface of the brass turning components, so that the surface roughness becomes larger. At this time, it is necessary to regrind or change the tool in time.

4. Prevent chips from roughening the machined surface of brass turning components. Chips will have irregular shallow scratches on the machined surface of brass turning components. Therefore, it is necessary to select the turning tool with positive blade angle to make the chips flow to the surface to be machined, and take appropriate measures to break the chips.

5. Prevent and eliminate vibration marks, select cutting oil reasonably, and ensure adequate cooling and lubrication.

We provide CNC Machining brass parts that meet the performance, quality, reliability, and safety requirements of our customers. And the design of reasonable detection fixture to ensure more efficient testing.

We offer industry-leading custom CNC Turning and milling brass. Our precision brass parts serve medical, communications, aerospace, drone, and robots. Providing the best CNC turning and CNC horizontal / vertical milling. Our extensive range of state-of-the-art CNC lathes and CNC Turning machines meet the tolerances of ± 0.01mm.

We have three types of CNC Machining Copper: copper, brass, bronze.

CNC machining brass including CNC Milling and cnc turning, cunting, grinding, milling, Sheet Metal Fabrication.

CNC Milling Machining and CNC turnining materials are: Aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6082. Steel: Q235, 45#, A3, 718H, S136, SKD11. Stainless steel: SUS303, SUS304,( 57504777, 57397823, 57276560, 57247539, 57198519, 57143741, 56439109, 56246764,1.4301), SUS316. Brass/ copper / bronze. Plastic: POM,PA,( 57504778, 57397824, 57276561, 57247540, 57198520, 57143742, 56439110, 56246766,PA66) PC, PMMA. Product surface treatment: anode (clear, black, blue, yellow, can also customize a variety of colors). Sandblasting, spraying, Passivation, laser engraving LOGO, silk screen LOGO.

CNC Machining brass can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : Machining Brass

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.