Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

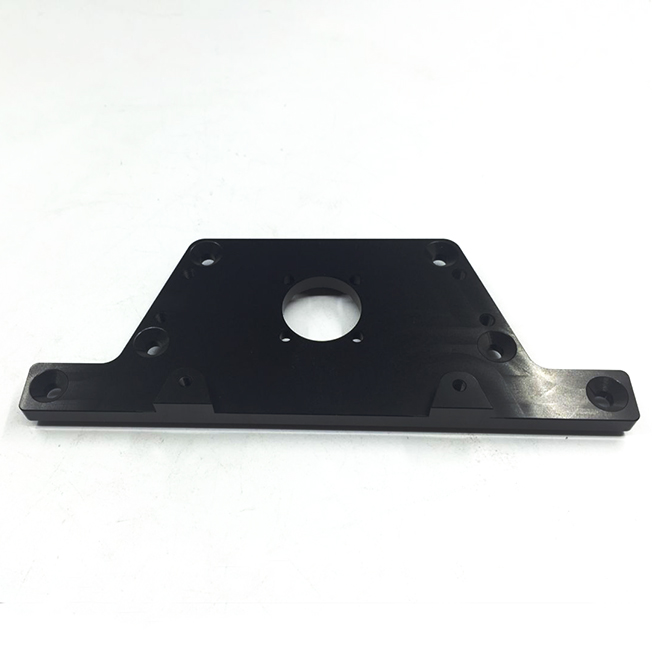

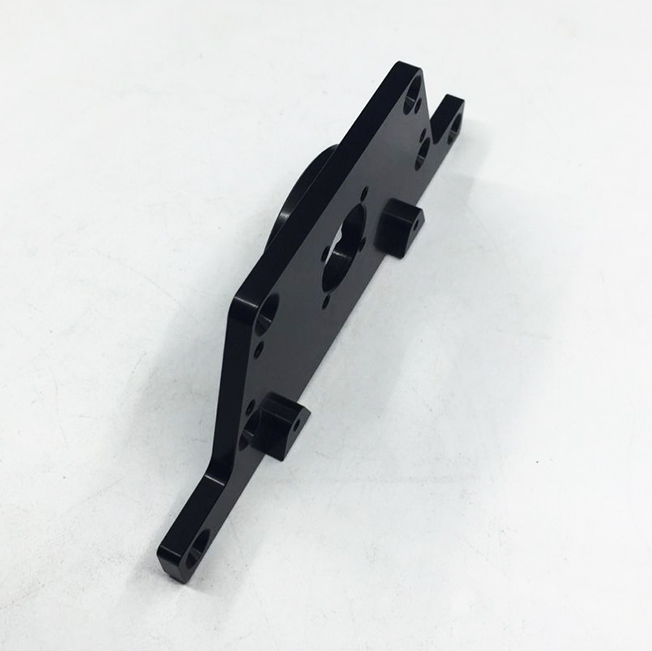

Model No.: AL-070

Tolerance: 0.01mm

Sample Lead Time: 3 Days

Material: Aluminum 6061

Finish: Anodise Black

Product Size(mm): 133.5*54*26

Productivity: 4600/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

The CNC precision Milling Aluminum parts is under the control command issued by the CNC system, and through the PLC control each execution part to rapid CNC Machining Aluminum parts. When rapid CNC Machining aluminum parts, in order to meet the requirements of the drawings to ensure the geometric tolerances, process analysis must be carried out. The purpose of the process analysis, first is examine parts of the shape and dimension precision, mutual position precision, surface roughness, material and heat treatment technology requirements are reasonable, whether convenient processing and assembly; Second is through the process analysis, further understanding of the process requirements of rapid CNC Machining aluminum parts, comprehensive consideration of machine tool the performance, selection of cutting parameters, cutting tool, clamping methods, CNC precision milling range and CNC precision milling methods, in order to make reasonable process specification.

We provide high-precision machining services:

1 Machining process: CNC Milling, CNC Turning, Sheet Metal Fabrication.

2 CNC machining range:Aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6083. Steel: Q215, Q235, 10#, 15#, 45#, S136, SKD11, 718H. copper / bronze / Titanium / TC4. Plastic: Delrin POM, Teflon, Nylon, PA, PC, PMMA, Ultem, PEI, PTFE. Stainless steel: 303, 304, 316, 430, 420. Secondary Services Offered: laser engraving LOGO, Anodizing, Plating Chrome, Nickel, RoHS Zin, Assembly Welding, Heat Treating, Powder Coating, Centerless Grinding.

3 CNC machining equipment: CNC machining center, CNC turning center, engine lathe, drill press, milling machine, grind machine.

The perfect ISO9001: 2008 quality system certification to ensure product quality. The quality personnel perform dimensional measurements on each piece of CNC machined parts. Measuring instruments: Digital caliper, Micrometer Calipers, height gauge, Profile projecto. Measurable accuracy of 0.01mm. In order to improve the speed of inspection, the engineers designed sophisticated auxiliary fixture. We provide dimensional reports of machined parts.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Product Categories : Machining Aluminum

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.