Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

[]

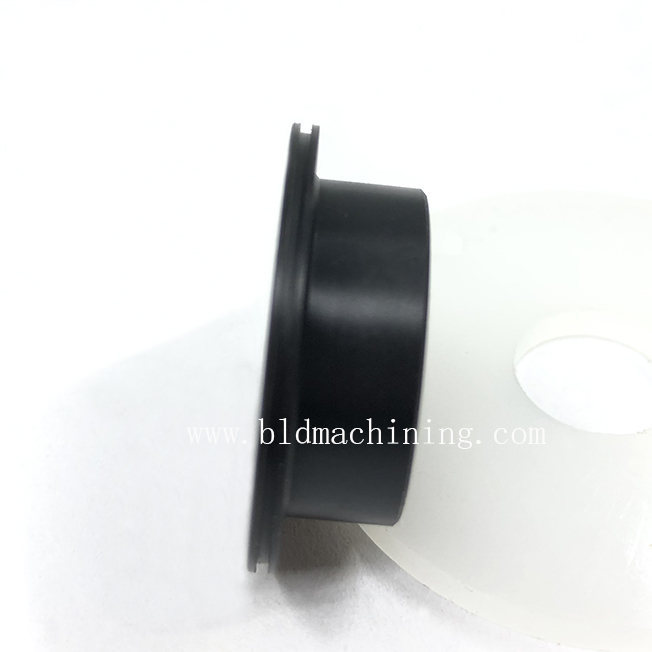

Model No.: TU-065

Material: POM

Tolerance: 0.01mm

Finish: NA

Sample Lead Time: 6 Days

Product Size(mm): ф30*20

Productivity: 4600/Month

Transportation: Ocean,Land,Air

Payment Type: T/T

Incoterm: FOB

[]

High Precision Lathe Turning Plastic Parts with Grooves

Lathe turning grooves Machining is divided into internal groove and external groove. The groove on this plastic turned parts belongs to external groove.

1. For rectangular grooves with low turning accuracy and narrow width, the slot cutter with the width equal to the width of the groove can be used, turning O-ring grooves is machined by direct feeding at one time. Lathe turning grooves with higher precision is usually made of secondary feeding vehicle. That is to say, when the first feeding trough is used, the finishing margin is left on both sides of the trough wall, and the second feeding trough is trimmed with an equal width knife.

2. Lathe turning wider grooves can be cut by multiple straight cutting. A certain amount of finishing allowance is left on both sides of the groove wall. Then, according to the groove depth and groove width, the finishing turning machining to the drawing size.

3. Turning small circular arc grooves, usually with forming cutter turning. Large circular arc grooves can be turned by linkage and checked and trimmed by template.

4. Turning small trapezoidal grooves is usually accomplished by forming cutter turning. Larger trapezoidal grooves are usually made by turning straight grooves first, then by using trapezoidal cutter straight-forward method or left-right cutting method.

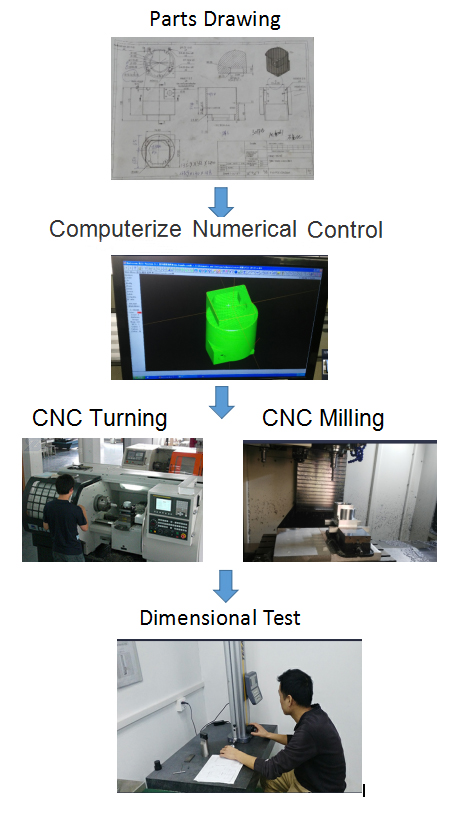

Powerful automatic precision turning team is to ensure that the basis of product quality, our engineers focus on continuously improving automatic precision turning turning and machining technology. A comprehensive understanding and master the CNC Turning and CNC Milling programming the basic process and key technologies. Proficiency in the use of CAD / UG / Master CAM software on the important processing procedures should be CNC Machining Turning test.

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. Our CNC Milling Machining and CNC turning materials are:

| Aluminum | 6061, 6061-T6, 6063, 7075, 5052, 2024, 2017, 6082 |

| Copper | Copper, Brass, Bronze |

| Stainless Steel | SUS303, SUS304,( 57333944, 57327748, 57266856, 57158587, 56720232, 56707289, 56674195, 56664771, 54400552, 54383354, 54153424, 54147929, 54138846, 54131278, 54067234, 54065431, 54025957,1.4301), SUS316 |

| Steel | Q235, 45 #, A3, 718H, S136, SKD11 |

| Titanium | |

| Plastic | Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, PMMA, PC, PAI, PPS, PA, PVDF, POM, PA, PET, PEI |

In addition, we also offer products for your secondary processing services: anodize (clear, black, blue, yellow, can also customize a variety of colors), Sandblasting, spraying, Passivation, laser engraving LOGO, silk screen LOGO.

Automatic precision turning can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Our characteristics:

Product Categories : CNC Machining Turning

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.