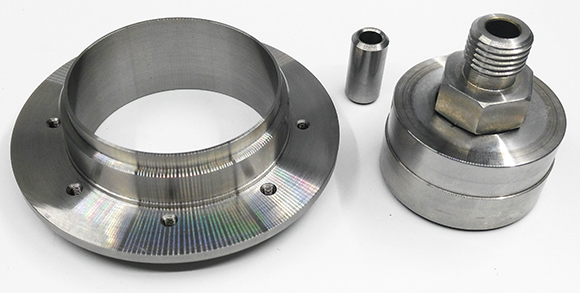

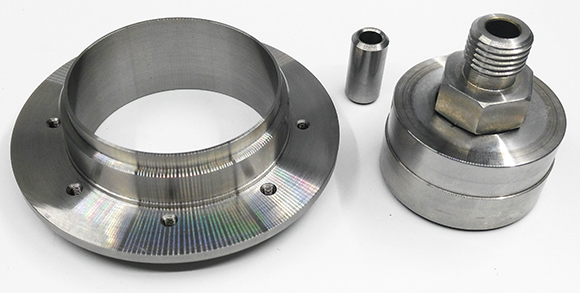

Stainless steel is a metal material that is relatively difficult to machine. There are two main problems in turning processing: ①Stainless steel has high high temperature strength and strong work hardening tendency, which is easy to wear and reduce tool life. ②Stainless steel has high toughness, chips are not easy to break, and easy to damage. The quality of the machined surface is also a threat to the safety of the operator. Therefore, chip breaking during turning is also a more prominent problem. In the long-term production practice of turning stainless steel parts, a stainless steel external turning tool has been explored

The different hardness of martensitic stainless steel after heat treatment has a great influence on turning processing. Table 1 shows the turning situation of 3Cr13 steel with different hardness after heat treatment with a turning tool made of YW2 material. It can be seen that although the hardness of the annealed martensitic stainless steel is low, the turning performance is poor. This is because the material has large plasticity and toughness, uneven structure, strong adhesion, and it is easy to produce cutting edges during the cutting process, and it is not easy to obtain good surface quality. . After quenching and tempering, the 3Cr13 material with a hardness below HRC30 has better workability and is easy to achieve better surface quality. Although the surface quality of the parts processed when the hardness is greater than HRC30 is better, the tool is easy to wear. Therefore, after the material enters the factory, the quenching and tempering process is performed first, and the hardness reaches HRC25-30, and then the cutting process is performed.

Selection of tool materials

The cutting performance of the tool material is related to the durability and productivity of the tool, and the manufacturability of the tool material affects the manufacturing and sharpening quality of the tool itself. Therefore, the tool material should be selected as a tool material with high hardness, good adhesion resistance and toughness. Under the same cutting parameters, the author has carried out a turning comparison test on tools of several materials. It can be seen from Table 2 that the external turning tool with TiC-TiCN-TiN composite coating blade has high durability and high surface quality of the workpiece. Good, high productivity. This is because the blades of this kind of coated carbide material have better strength and toughness, and because the surface has higher hardness and wear resistance, smaller friction coefficient and higher heat resistance, and It has become a good tool material for turning stainless steel on CNC lathes, and the first choice for external turning tools for

Machining 3Cr13 stainless steel. Since there is no cutting blade of this material, the comparison test in Table 2 shows that the cutting performance of YW2 cemented carbide is also good, so the blade of YW2 material can be used as the cutting blade.

Selection of the geometrical angle and structure of the tool

For a good tool material, it is particularly important to choose a reasonable geometric angle. When

Machining Stainless Steel, the geometry of the cutting part of the tool should generally be considered from the choice of rake angle and back angle. When selecting the rake angle, factors such as the flute profile, the presence or absence of chamfering and the positive and negative angle of the blade inclination should be considered. Regardless of the tool, a larger rake angle must be used when machining stainless steel. Increasing the rake angle of the tool can reduce the resistance encountered during chip cutting and removal. The selection of the clearance angle is not very strict, but it should not be too small. If the clearance angle is too small, it will cause serious friction with the surface of the workpiece, worsening the roughness of the machined surface and accelerating tool wear. And because of the strong friction, the effect of work hardening on the surface of stainless steel is enhanced. The tool relief angle should not be too large. If the relief angle is too large, the wedge angle of the tool is reduced, the strength of the cutting edge is reduced, and the wear of the tool is accelerated. Generally, the relief angle should be appropriately larger than when processing ordinary carbon steel. Generally, when turning martensitic stainless steel, the rake angle g0 of the tool is preferably 10°-20°. The relief angle a0 is suitable to be 5°~8°, and the maximum is no more than 10°.

In addition, the blade inclination angle ls, the negative blade inclination angle can protect the tip and improve the strength of the blade. Generally, g0 is selected from -10° to 30°. The entering angle kr should be selected according to the shape of the workpiece, the processing location and the tool installation. The surface roughness of the cutting edge should be Ra0.4~0.2µm.

In terms of tool structure, externally inclined circular arc chip breakers are used for external turning tools. The chip curling radius at the tip of the tool is large, and the chip curling radius at the outer edge is small. The chips turn to the surface to be machined and break, and the chip breaking is good. . For the cutting tool, the secondary deflection angle can be controlled within 1°, which can improve chip removal conditions and extend the service life of the tool.

Reasonable choice of cutting amount

The amount of cutting has a greater impact on the surface quality of the workpiece, the durability of the tool, and the processing productivity. The cutting theory believes that the cutting speed V has the greatest impact on the cutting temperature and tool durability, followed by the feed f, and ap the smallest. The depth of cut ap is determined by the size of the workpiece on the surface processed by a tool on a CNC lathe. Determined by the size of the material blank, generally 0~3mm. The cutting speed of difficult-to-machine materials is often much lower than that of ordinary steel, because the increase in speed will cause severe wear of the tool, and different stainless steel materials have their own different optimal cutting speeds. This optimal cutting speed is only It can be determined by experiment or by consulting relevant information. When machining with cemented carbide tools, generally recommended cutting speed V=60~80m/min.

The feed rate f has less impact on tool durability than cutting speed, but it will affect chip breaking and chip removal, thereby affecting the strain and abrasion of the workpiece surface, and affecting the surface quality of processing. When the roughness of the processed surface is not high, f should be 0.1~0.2mm/r.

In short, for difficult-to-machine materials, a lower cutting speed and a medium feed amount are generally used.

Choose proper cooling and lubricating fluid

The cooling lubricant used for turning stainless steel should have high cooling performance, high lubrication performance and good permeability.

The high cooling performance ensures that a large amount of cutting heat can be taken away. Stainless steel has high toughness, and it is easy to produce built-up edge during cutting and deteriorate the machined surface. This requires the cooling lubricant to have higher lubricating performance and better permeability. Commonly used processing stainless steel cooling lubricants include sulfurized oil, sulfurized soybean oil, kerosene plus oleic acid or vegetable oil, four-grained carbon plus mineral oil, emulsion, etc.

Considering that sulfur has a certain corrosive effect on the machine tool, vegetable oil (such as soybean oil) is easy to attach to the machine tool and become stale and deteriorate. The author chose a mixture of four-handed carbon and engine oil in a weight ratio of 1:9. Among them, the four-handed carbon has good permeability and good lubricity of engine oil. Tests have proved that this cooling lubricant is suitable for semi-finishing and finishing processes of stainless steel parts with small surface roughness requirements, and is particularly suitable for turning processing of martensitic stainless steel parts.